Add to Cart

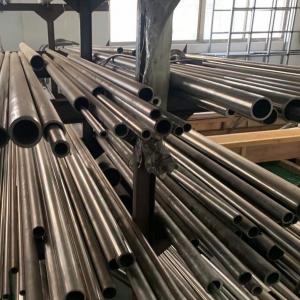

Cold Drawn 304 Stainless Steel Pipe ASTM A312 Seamless Stainless Steel Tube Diameter 6 - 76mm

| Description | stainless steel sanitary mirror pipe and high purity clean pipe |

| Section Shape | round/customized. |

| Material range | 304, 304L, 316L, 321, 310S, 347H, Ni-based alloy, 316Ti, duplex steel, and ETC. |

| Od(mm) | 6mm~76mm |

| Wall Thickness | 0.89mm~15.0mm |

| Length | 3-8 Metre/Customized |

| Tolerance | According to the Standard you require |

| Suface Treatment | Bright with oil |

| Transport Package | Standard Sea-Worthy Packing/customized |

| Trademark | Sailing/customized |

| MOQ | 1 piece( can provide samples) |

| Productivity | 3000 Ton Per Month |

| Certificate | CE, GOST,PED by TUV, ISO9001 |

| Standard | GB/ASTM/ASME/DIN/EN/JIS |

| Origin | China |

| Usage | Pharmacy, biochemistry, fine chemical industry, CDA, Bulk gas, Ro water, pure oxygen, Pure nitrogen, Injection water, food, dairy products, brewage, etc |

What is cold drawn stainless steel pipe

Precision pipe is the carbon, alloy or stainless steel pipe with high precision sizes. Usually it has been made through hot rolling or cold drawn (cold rolling) processes. So precision pipe is a kind of seamless pipe.

It is designed with several advantages:

Inside and outside surface no oxide coating;

It could bear high pressure, no leaking;

Strict less tolerance;

Surface smooth;

No reformation in cold bending, no cracks during flaring test, and flattening test.

With these advantages it is widely used for manufacturing the pneumatic parts and hydraulic components.

Size tolerance of our stainless steel pipe

For hot rolling precision steel pipe, tolerance of OD is +/- 0.1%.

For cold drawn precision pipe, tolerance allowed in below conditions:

Diameters 6mm to 10mm, normal tolerance condition +/- 0.2%, premium tolerance condition +/- 0.15%.

10mm to 30mm, normal tolerance condition +/- 0.4%, premium tolerance condition +/- 0.2%.

30mm to 50mm, normal tolerance condition +/- 0.45%, premium tolerance condition +/-0.3%.

For outer diameters above 50mm, normal tolerance condition +/- 0.1%, premium tolerance condition +/- 0.8%.

a. You can get a smaller diameter with precision steel pipe

b. High precision pipe accept small quantity for MOQ.

c. The pipes with cold drawn processes has high precision and good surface finish.

d. The transverse area of the steel pipe is more complicated.

e. Performance is superior, with higher density.

During manufacturing processes, the key point is to do the annealing for raw materials.

Precision steel pipe manufacturing flow chart:

Raw Material Inspection – Remove Oxide Layer – Visual Inspection – Heating – Hot Rolling – Pickling and Passivation (Phosphating) – Grinding – Lubrication and Drying – Cold Rolling (Internal and external extraction) – Remove Oil – Ends Cutting – Inspection – Marking – Packing and Storage

As we know, most of precision steel pipe has cold drawn and hot rolled process. On the contrast, cold rolling will be more complicated. Not only the pipe need to be continuous rolled by three roller, but also the test have to be done after extrusion, so to guarantee the quality of the precision pipe materials.

Manufacturing methods of seamless precision pipe includes hot rolling and cold drawn. More over it could be manufactured in welding processes.