Add to Cart

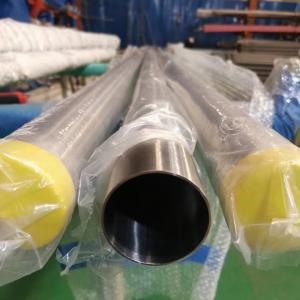

304 316L BA Grade Stainless Steel Pipe & Tube Bright Annealing SS Pipe Diameter 4 - 89mm

| Products Name | 304 Stainless Steel Pipe |

| Pipe Type | Seamless Pipe . Welded Pipe |

| Surface | Pickling , polishing |

| Out Diameter | 6 - 508mm |

| Wall Thickness | 1.0 - 50.0mm |

| Length | 6m or cutting any length as request |

| Standard | ASTM / GB / EN / DIN / JIS / BS / BIS |

| Mainly Grade | 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 2205 2507 904L 254SMO 800/800H Alloy20 ,Hastelloy Alloy, Monel Alloy,Inconel Alloy |

| Service | Cutting, Polishing, Hairline Finishing |

| MOQ | 200 Kgs |

| Packing | standard packing for export |

| Application | Industrial , food , medical, househould |

Bright Annealed Tube Technical Data:

1) BA Tube Description:

Bright Annealed Tubes | BA Tube | Bright Annealed Stainless Steel Tubes | Bright Annealed Stainless Steel Tubing

2) BA Tube Specification:

ASTM A213 / A269 / A632

DIN 17458 / ISO 1127

3) BA Tube Reference Sizes:

6.35×0.89, 9.53×0.89, 12.7×1.24, 19.05×1.65, 25.4×2.11, 3/8, 5/8, 1/2, 3/4, 1, 11/4, 11/2, 2

Special sizes can be made to order.

4) BA Tube Advantages:

a. good dimensional accuracy

O.D.: +/-0.05mm, W.T.: +/-0.05mm

b. excellent surface roughness

outside surface: Ra < 0.6um, inside surface: Ra < 0.3um

5) BA Tube Main Production Equipments:

2 sets of Cold Drawing Machine with Floating Mandrel

6 sets of Cold Pilger Machine with Three Roller

2 Sets of Bright Annealed Furnace with Pure H2

Our BA Tube are widely used in the fields of precision instruments, oil & gas service, precise mechanical parts, semiconductor industry, bio-pharmaceutical, etc

Textile Industries

Precision instruments and parts

Medical eauipment apparatus

Electronic and electric appliance

Automatic apparatus

Opto-electrical and semi-conductor

1. Heat Treatment and Solution Annealing / Bright Annealing

2. Cutting to required length and deburring,

3. Chemical Composition Analysis Test With 100% PMI and One tube from each heat by Direct Reading Spectrometer

4. Visual Test and Endoscope Test for Surface Quality Test

5. 100% Hydrostatic Test and 100% Eddy Current Test

6. Ultrasonic Test subject to the MPS (Material Purchase Specification)

7. Mechanical Tests includes Tension Test, Flattening Test, Flaring Test, Hardness Test

8. Impact Test subject to Standard request

9. Grain Size Test and Intergranular Corrosion Test

10. Ultrasoic measuring of Wall Thickness